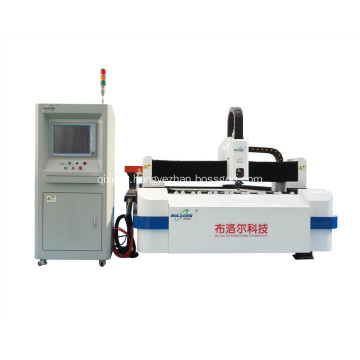

Fiber laser cutting machine for carbon steel

Fiber laser cutting machine for carbon steel

| Payment Type: | T/T |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 20 Days |

| Packaging: | Steel Box |

|---|---|

| Brand: | Buluoer |

| Transportation: | Ocean,Land |

| Place of Origin: | Ji'nan City, Shandong Province, China |

| Supply Ability: | 200set/month |

| Certificate: | ISO9001 CE |

| Port: | Qingdao Port,Shanghai,Guangzhou |

Basic Info

Model No.: CE 3015 CE4015 CE4020 CE6020

Click on the follow link to find out more information: https://www.buluoercuttingmachine.com/fiber-laser-cutting-machine/

Company Info

- Company Name: Shandong Buluoer Intelligent Technology Co., Ltd.

- Representative: Jing Fengquan

- Product/Service: Fiber Laser Cutting Machine , Flame Cutting Machine , Metal Cutting Machine , CNC Plasma Cutting Machine , Gantry CNC Cutting Machine , CNC Fiber Laser Cutter

- Capital (Million US $): 110 Million

- Year Established: 2014

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 11% - 20%

- Total Annual Purchase Volume (Million US $): US$2.5 Million - US$5 Million

- No. of Production Lines: 5

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: No. 666 Fengnian Av., Mingshui Economic Zone, Zhangqiu District, Ji'nan City, Shandong Province

- Contact Person: Ms. Alisa Yu

- Tel: 0531-18668937296

Premium Related Products

Other Products

Hot Products

Replacement for DAIKIN servo valve filter elementsupply nature gas filter MCC1401E100H13,Natural gas filter MCC1401E100H13Preferred Filter Manufacturer DEMALONG Large flow condensate water filter element HFU660UY100J,Large flow water filter cartridgeWholesale Good quality 180 micron suction oil filter element ZX-160X180 replacementNew Product ! ! ! Supply OEM Fiber Filtration Parts,OEM Metal Material Stainless Steel Filter Element from china supplierHX100*10 Durable and reliable stainless steel mesh Replacement leemin hydraulic filtersSupply high quality air breather P171784 used for tankDemalong supply high effectiveness Lubricating oil filter cartHOT SALE vacuum pump oil filter 730503Excellent quality of fuel filter 614080739A replacement Weichai filterPretty good quality sale 202 mesh filter disc type oil filter SPL-40liquid level controller YKJD24.BH-650-450-150Turbine coalescer filter element 95-137C-G3/4" Air breatherfilter element 32.060.L2.VSupply many types air compressor 1613740800 air filter